£120.00

Description

The RYA Diesel Engine course, is a one-day beginners’ course to help you prevent and solve diesel engine failure.

Mechanical failure is the main cause of rescue call-outs to cruisers. Basic maintenance and engine care will help ensure that you are not part of this statistic.

Most engine problems can be avoided by taking simple precautions, and you don’t need a detailed mechanical knowledge.

This course teaches you how your engine works, how to keep it healthy by using basic checks and maintenance procedures, and how to get it started again in the event of a breakdown.

Whether you sail a yacht with an auxiliary diesel engine or are a motor cruising enthusiast, the RYA Diesel Engine course could not just save you money, but one day could save your life.

The course costs £120 and includes an RYA pack that will help you through the day and that you will be able to take away with you. Your certificate is also included.

Courses are held in Wickford, Essex. 10 minutes from Junc 29 of the M25 or by train, 35 minutes from London Liverpool St.

- the principles of diesel engine operation

- the systems and parts of the engine

- fault finding

- rectification of common problems

- bleeding the fuel system

- changing the impeller

- routine maintenance

- winter lay up procedures

Click here for available dates

Full RYA Diesel Engine SyllabusThis one day course provides an awareness of the main systems of a marine diesel engine and teaches the ability to take simple measures to prevent mechanical breakdown at sea and rectify defects which do not require workshop support. Mechanical failure is the main cause of lifeboat callout to yachts and motor cruisers. Basic maintenance and engine care may make sure you are not part of these figures.

1. Introduction

Principles of the diesel engine

2. The four-stroke cycle

Naturally aspirated engines

Turbocharging

Intercooling / aftercooling

3. The fuel system

The basic system

The tank

The water-separating pre-filter

Fuel lift pump

The engine fine filter

Injection pump

Injectors

Bleeding the system

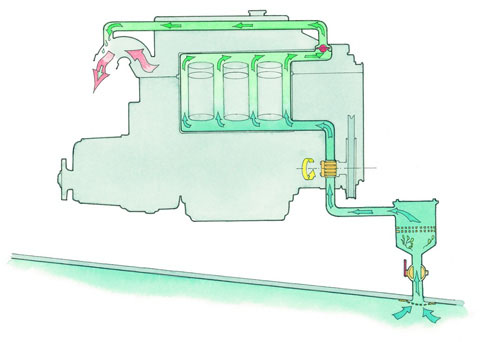

4. The cooling system

Seawater cooling

Freshwater cooling

Temperature control

The thermostat

The seawater impeller pump

5. The air systems

The airway in

The airway out

6. Engine electrical systems

The basic system

Battery capacity and care

Drive belts

The alternator

7. Spares and tool requirements

Basic spares and tools

8. Importance of winterisation and servicing

Engine lubrication

Transmission lubrication

Winterisation and servicing

Service schedule

9. Fault finding

Top tips to help keep you going.

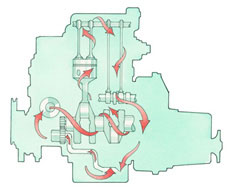

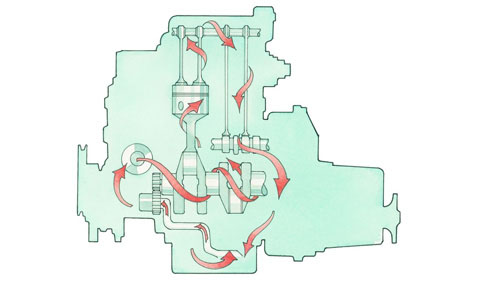

Modern marine diesel engines are pretty reliable things – most of the time. Feed them with diesel and air, cool them with seawater/coolant and add sufficient lubricant to keep the cogs turning and they will often give hundreds or thousands of trouble free hours.

However we all have our off-days and diesel engines are no exception. Knowing a few troubleshooting tips will go a long way to keeping you going.

Safety

When checking the engine, isolate the engine battery and remove the engine keys, so that others cannot start the engine whilst you have hands in the way. Consider using plastic/latex gloves.

Cleanliness

Be fastidious about keeping the engine compartment clean. It makes spotting a potential leak or problem so much easier.

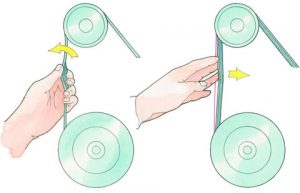

Belts

The crankshaft, usually the pulley wheel at the bottom of the engine, usually drives the belts. Belts transfer power to other pulley wheels on the engine and drive the alternator, to provide power to the batteries, and the water pump to circulate cooling water around the engine.

If the belt is too loose:

- The alternator may be inefficient resulting in uncharged batteries.

- The water-circulating pump may be inefficient resulting in the engine running hotter.

- Regularly checking gauges such as the voltmeter and engine temperature will highlight both of these problems.

A slipping or loose belt is often visually indicated by black belt dust around the engine near the pulleys. There are two common types of belt; flat belts or ‘V’ shaped. Consult your owner’s manual about their accurate testing and adjustment, but a common rule of thumb to check adjustment is:

- V Belts can be deflected by about 12mm and no more.

- Flat belts should be able to twist through 90 degrees and no more.

A belt adjusted too tight can put excess pressure on the pulley wheel shaft and increase wear on the shaft bearings of the pulley wheels.

Oil

A properly functioning engine does not really consume much lubricating oil; it just uses the oil to lubricate and cool its moving internal parts. So if the correct level is checked it should stay roughly the same and only change over longer periods, unless there is a problem. Oil is kept inside the engine and separate from the water and fuel system by internal seals and gaskets.

The ways that oil escapes from the engine is by leaking through an engine seal or gasket. There are three visual ways to check for oil leaks:

- 1) Externally looking for leaks around the engine and engine tray

- 2) Oil leaking through a seal and mixing with the water cooling system.

- 3) Oil leaking into the combustion chamber, through the piston rings and coming.

The oil will burn in the combustion chamber and change to blue smoke coming out of the exhaust.

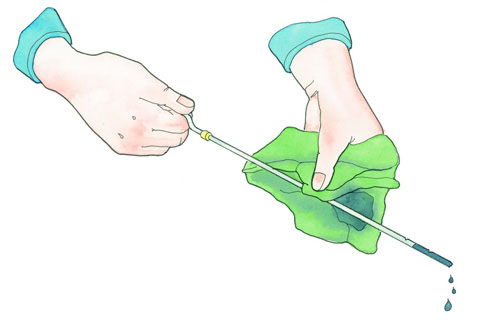

Oil levels need monitoring and too much or too little oil is bad for the engine. Looking at the condition of the oil is a little like reading tealeaves.

- Green/brown oil is often clean oil in good condition.

- Black oil is oil that has picked up carbons or soot, is starting to age and could possible need a change.

- Grey or emulsified oil possibly has water mixing and may signify an internal leak. Contact an engineer.

- Burnt smelling oil could be due to overheating.

- Particles in the oil could be pieces of worn engine. Contact an engineer.

Cooling

Many modern marine diesel engines have both seawater cooling and fresh water cooling. The seawater cools the fresh water/coolant that circulates around the engine.

Checking the seawater intake strainer is the main check on the seawater system apart from running the engine and ensuring that seawater is exiting through the exhaust (if you can see it). The exiting seawater water also quietens and cools the exhaust so if water is not passing through the exhaust, the exhaust note sounds hollow.

Times when seawater circulation can be a problem are:

- On a sailing yacht at heel – if the water intake seacock is out of the water.

- Outdrives and sail drives pick up their cooling water through the drive unit and these easily get blocked by polythene bags or lumps of seaweed in the water wrapping themselves around the drive. Often slowing the boat or reversing gently will clear the obstruction.

- If the seawater strainer is blocked or the water circulating pump or impellor malfunctions.

- If the overheat alarm sounds

A way of establishing whether the seawater or freshwater system is the problem when the overheat alarm sounds, is to:

- Reduce the revs but keep the engine running

- If water is normally visible exiting through the exhausts, check if it still is exiting. If it is, then the seawater system is probably working ok and the problem will probably be with the fresh water system.

- Check the temperature gauges, a reduction in revs may reduce the temperature.

- If not stop the engine and deal with the problem.

Want to know more about diesel engines, then why not join one of our courses? just (click here) to find our next avaialable date then click the “Booking button” to book.

Things to consider to protect your boat through winter

“When putting your boat to bed for the winter there are a few things to consider to protect it through the winter months”, explains RYA Chief Instructor, Motor Cruising and Power, Rachel Andrews. “This list is by no means exhaustive but it will give you a few top tips”.

Use it. The best way to winterise a boat is to use it as it’s designed to move. A boat contains a multitude of systems that hate inactivity – particularly the engine.

There are plenty of other items that would benefit from winterisation but if you only do one thing, do it on the engine.

1. First on the list – general engine cleaning and observation. Shine plenty of light, use a mirror on a stick or a digital camera to see under and behind things. Dry the bilges to prevent corrosion and if necessary, paint them white to highlight any leaks and drips in the future.

2. Whether your boat is being hauled out for the winter or not, fill your fuel tank to prevent condensation, which in turn prevents the growth of diesel bug.

3. Change the engine oil and replace the oil filter before leaving your boat for the winter. Leaving the old oil contaminated with the acidic by-products of combustion inside the engine block will shorten the engine’s life and a neglected oil system will cause expensive damage. Also consider using flushing oil or a flushing additive during the oil change which helps to remove more of the contaminants.

4. Check the gearbox or outdrive oil and replace if it looks cloudy or milky.

5. Most diesel engines use either raw water or keel cooling – both of which need attention when winterising. Raw water systems require draining before leaving for the winter, by closing the water inlet valve, or sea cock, disconnecting a hose from the circulating pump, (unless there is a dedicated tap or plug), then refilling with a strong solution of fresh antifreeze. Run the engine to fully circulate the new solution. Simply draining the system is unlikely to remove all the water inside, which may then freeze and cause damage over the winter.

6. Check the water pump impeller and consider replacing it when de-winterising in case the blades have deformed over the winter. Keel cooling systems can be left alone providing they contain the correct water/antifreeze mixture. This can be checked using a strength tester available from marinas and good car spares outlets. Note that antifreeze has a limited life and if it has to be replaced then it is a good time to replace any suspect hoses. Keep the old hoses as emergency replacements.

7. Remove the air intake filter and block the intake with an oily rag to prevent rust inside, do the same for the exhaust. Squirt a little oil into the intake and turn over the engine, (without starting), to distribute it over the cylinder walls. Be sure to place a warning about the blocked intake on the engine control panel to prevent anyone turning the engine over.

8. Where possible, remove the batteries and keep them warm and dry over the winter, fully charged or topped up at least every four to six weeks. Batteries left uncharged for long periods may need to be replaced completely. If you’re unable to remove batteries or if the boat is staying on its mooring, leave them fully topped up and regularly recharged, as full batteries are less likely to freeze in sub-zero temperatures.

9. Relax or remove all belts and protect the drive wheels. Rust on these can chew up a belt very quickly in the new season.

10. If you’re taking the boat out of the water make sure it is angled bow upwards slightly to enable rain water to run off immediately from covers, decks and cockpit.

11. Covers should keep water out but allow air to circulate. Proper through-draught will prevent condensation which leads to dry rot, mould and corrosion (especially if left for more than a single season).

12. The internal freshwater supply system also requires attention. Drain the entire system including tank, pump, calorifier, water filters and all taps especially shower mixers. Look for any areas where water could still be trapped in pipes. Plastic piping is less vulnerable than copper piping but rigid unions can still be damaged by freezing.

13. If you have a water-based central heating system using antifreeze then the same checks carried out to the keel cooled engine system should be applied. If the system doesn’t use antifreeze then it should be drained as for the freshwater supply.

14. Remove any foodstuffs which may be damaged by the frost or attract unwanted visitors such as mice and rats.

15. Store all linen, clothing, blankets, curtains etc. ashore – washed and dry. Prop the fridge door open – mould will form in less than a week if left closed. Ensure through-ventilation. Leave cupboards and drawers open; prop up bunk cushions, leave under-berth locker lids open. Get circulation into every possible conceivable nook and cranny.

16. Ensure tight-fitting covers for deck-installed electronics and consider spraying behind electronics with water-repellent silicone. Check your navigation lights are still serviceable.

17. If leaving the boat afloat, check all through hull fittings for leaks and corrosion. Don’t forget to check your stern glands and repack with grease if appropriate.

18. Make a list of what you have done to winterise the boat so you remember what to reverse in the spring and leave signs all around the boat so no-one accidentally operates a winterised system.